PROCESS ENGINEER

JOB DESCRIPTION

Provides leadership and technical oversight to the Actual Process Development and Validation Activities. Included is the responsibility to take on the leadership role in the entire scope of the Actual Machine Process Development and Validation Cycle, making sure all operation targets and quality expectations are met.

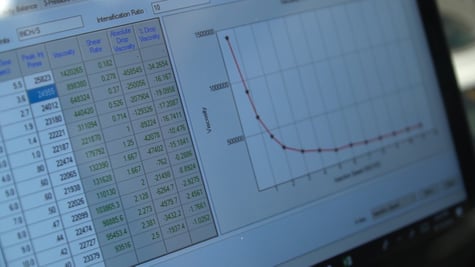

- Develop the injection molding process of new products and documents.

- Monitors the plastic process to provide manufacturing improvements, quality improvements, or cost reductions

- Integrates plastic process development forethought in parallel with production tool design to support program objectives.

- Researches new plastic technologies and opportunities for the advancement of our products and processes

- Monitors and controls objectives, costs, and timetables of plastic product process development and validation.

- Manages process validation development projects for optimal delivery, quality, and cost

EDUCATION AND EXPERIENCE

REQUIRED

- Associates degree in Process Engineering or related discipline; or 4 year Vocational/Technical School certification/apprenticeship program; or

- 7 years experience in tooling design and development; and 5 years experience in hands-on process development for injection molding

- Must be able to read and understand mechanical drawings

PREFERRED

- Experience in medical device or pharmaceutical manufacturing requirements

- Direct experience in the manufacture of class I and II medical devices and ISO 13485

MOLD MAINTENANCE TECHNICIAN

JOB DESCRIPTION

Uses technical skills to clean, refurbish, and maintain molds and tools for injection molding operations while following established procedures, safety protocols, and documentation standards.

- Repairs and maintains tools, molds, and frames according to established procedures and best practices using a Work Order system.

- Records activities and time completing repairs in the ERP system

- Utilizes skills and best judgment to make repairs and improvements, consulting with Tooling Manager as a subject matter expert.

- Creates and maintains detailed documentation on the cleaning and servicing procedures for molds, enabling others to be trained using these comprehensive documents.

- Stays current with mold maintenance and best repair practices, technologies, and opportunities for the improvement of our products and processes

- Maintains an orderly workplace built around the principles of 5S

EDUCATION AND EXPERIENCE

REQUIRED

- Associates degree in Mechanical Engineering, Machine Tool Technology, or related discipline; or

- 4-year Vocational/Technical School certification/apprenticeship program; or

- Equivalent combination of education and experience.

- Must be able to read and understand mechanical drawings

PREFERRED -

Journeyperson tool maker or mold maker strongly preferred

MATHEMATICAL SKILLS

- Ability to work with mathematical concepts

- Basic trigonometry, geometry, fractions, percentages, ratios, and proportions

- Ability to define problems, collect data, establish facts, and draw valid conclusions

JOURNEYPERSON MOLD MAKER

JOB DESCRIPTION

Supports Product Manufacturing by constructing and repairing molds and machine parts using experience, skill, and good judgment.

- Completes assembly by bolting and doweling parts and components together, installing tools in mold frame, hydraulic or air cylinders

- Demonstrates competency in specialty skills such as welding, Wire EDM, electrode modeling, Hot Runner Maintenance, repair, etc.

- Machine Parts by measuring, marking, and scribing stock, setting up and operating lathe, mill, radical drill, grinders, CNC machining centers, etc.

- Completes preventative maintenance requirements following manufacturers' instructions; troubleshooting malfunctions; fills out maintenance request form

- Resolves assembly problems by making revisions where needed; Consulting with lead tool & die maker to obtain additional resources.

- Completes required training and logs machining experience within four years of employment. Completes duties with increased supervision and decreased skill & efficiency expectations.

"What I like most about working at Crescent Industries as a Mold Maker is being able to use critical thinking and new technology to produce products that positively affect everyone's day to day lives."