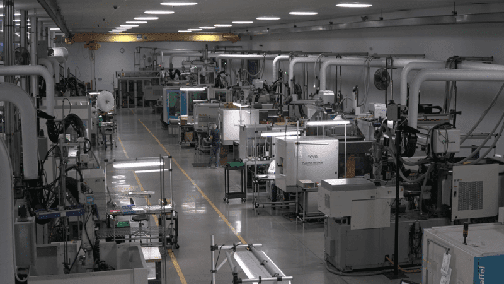

Custom Plastic Injection Molding

Post-Processing Services

To complete your project and reduce your supply chain, Crescent offers parts decorating, plating, annealing, shielding and more to finish your product.

Why Crescent is Different...

- Project Management Office includes R&D presses for setting and sampling new injection mold builds.

- We make available master action mold frames to house customer's tooling during production runs, providing a quality production tool at a lower cost.

- 100% invested in Quality standards with our state-of-the-art quality lab and equipment.

- We are an ESOP company, so every employee is invested in Crescent and our clients' success.

- We establish our processes using scientific injection molding, decoupled II, and decoupled III molding.

- Industry 4.0 monitors the molding machines' parameters and reports live data for instant manufacturing decisions to reduce defects and errors.

- Manufacturing and designing solutions to scale-up production when you are ready

- Supplying our customers with quality injection molds and components for 75 years

Committed to Manufacturing Solutions

At Crescent, we pledge our best effort to satisfy our customers’ requirements regarding quality, service, value, and delivery.

Custom Injection Molding Capabilities

Medical / Pharma / Dental

Our ISO 13485:2016 certified & FDA registered facilities include Class 10K & 100K clean rooms that allow us to handle the most complex Class I, II, III precision medical components and devices.

Military & Defense Molding

Our ITAR Registration & FFL allows us to work with a wide range of products and assemblies in the most sensitive applications. Whether it's a simple component or part of an integral system.

Custom Molding

Our extensive value-add capabilities provide competitive solutions for your supply-chain needs by implementing QRM, collaborative robots, and complete automated work cells.

Engineering Services

At Crescent, engineering is at the core of our plastic injection molding services. Our engineers specialize in assisting customers through all product stages, from conception into production. Our integrated single-source solutions provide our customers with complete Program Management Offices that offer a vast range of Design & Development services to manage the complexities of your project.

- Design for Manufacturability (DFM)

- 2D drawings & 3D CAD Models

- Project Management Offices

- Full-Service Integration

- Mold-Designs

- 3D-Printing (Additive Manufacturing) for Prototypes

- Mold-Fill Simulation

- Material Selection

Kitting & Value Add

As one of the leading injection molding manufacturers, we offer the most comprehensive range of value-added-services and secondary operations to solve the most difficult product assembly projects and complex production issues. All of our kitting & value add operations can be performed (if required) within our Class 10K or Class 100K Clean Room Facilities.

- Device Assembly

- Product Packaging

- Laser Engraving

- Pad Printing

- CNC Machining

- Ultra-Sonic Welding

- EMI or RFI Shielding

- Heat-Staking Inserts

- Solvent or UV Bonding

- Ultra-Sonic Cleaning

- Silk Screening

- Cap-Lining

- Annealing

- Vacuum/Pressure Test

- Sterilization Ready

Tooling Capabilities

Our journeymen mold builders produce injection molds that provide cavity-to-cavity consistency and repeatability by utilizing high-speed CNC mills, die-sink EDM, and wire-sink EDM.

- In-House Full-Service Toolroom

- Single-Cavity to 96+ Cavity Molds

- Master Unit Dies (MUD) + dedicated molds

- SPI 101-103 Mold Classifications Guidelines

- Documented intake process for tool transfers

- Tool Design for Manufacturability

- Actions, lifters, and unscrewing

- Valve-gate, hot-tip, cold-runner, 3-plate

- Documented Mold Maintenance, Mold Revisions, and Mold Repair Services