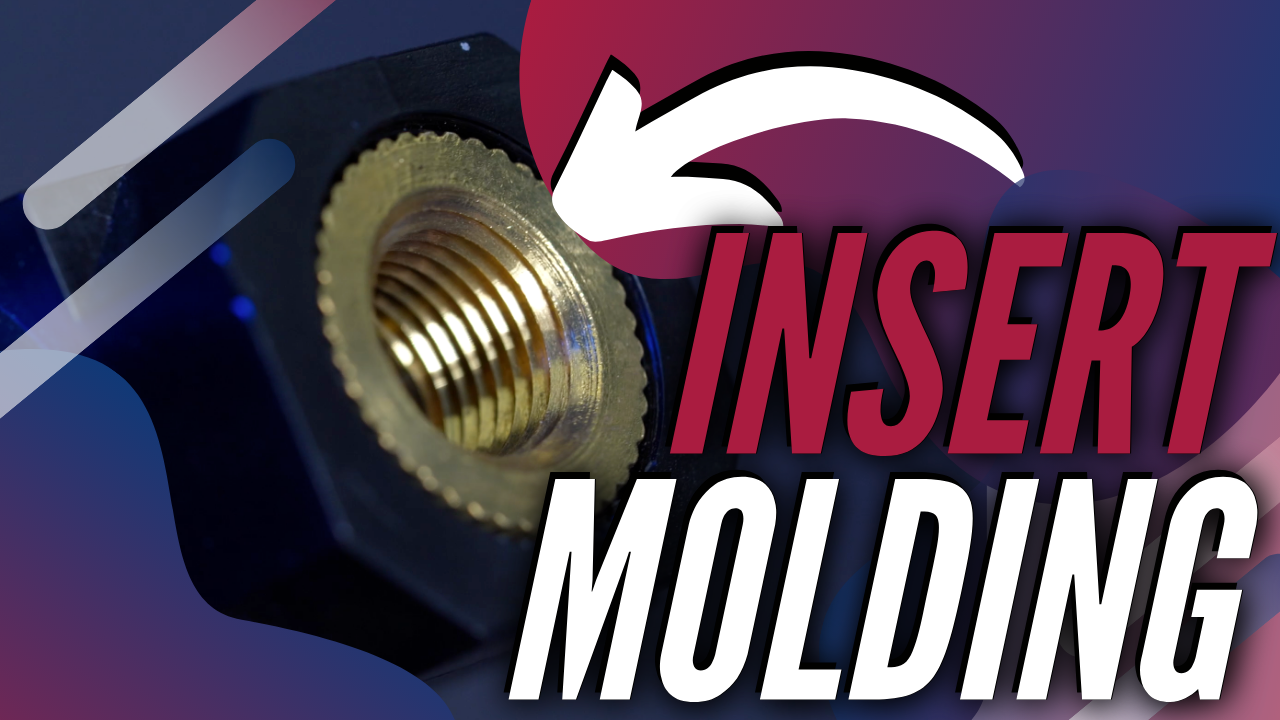

INSERT INJECTION MOLDING

Insert molding is a highly efficient and cost-effective process that allows for the creation of complex assemblies in a single step. At Crescent Industries, we specialize in insert molding services, and our team of experts has the knowledge and experience necessary to ensure that the metal-to-plastic bond is precise and strong.

By first designing the mold with careful consideration of the inserts and parts, our mold builders will ensure the tooling will have a good seal during the insert molding process, resulting in a finished product that meets the highest standards of quality and functionality.

Whether you need a simple insert or a complex assembly, Crescent Industries has the expertise and technology to deliver the perfect solution for your injection molding needs.

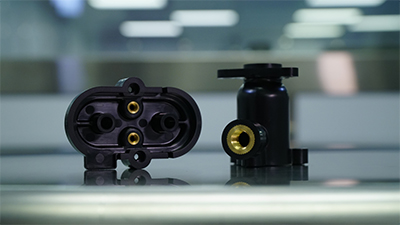

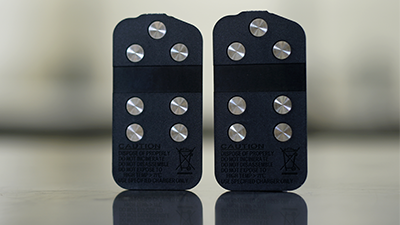

Samples of Crescent's Insert Injection Molding

Insert molding is used in a broad range of industries for a variety of uses and applications. At Crescent, we use vertical/vertical injection molding presses to help leverage gravity to keep the insert in place during the molding process.

We primarily focus on insert molding for the following industry sectors: Medical Device, Defense, and Industrial/OEM applications.

Crescent Industries for your Insert Injection Molded Project!

Manage the entire insert molding process, starting with mold design, fabrication, production, and manufacturing of the inserts if needed.

They are used in Housings, Instruments, Knobs, Electric Components, and more!

Insert injection molding is just one aspect of our overall injection molding expertise. Our full suite of services delivers the highest quality and integrity our customers expect and deserve. Whether you need injection molding services from design to production or seek assistance in a single area of your development cycle, we are here to help.

- DFM and Engineering Support

- New Injection Mold Builds In-House

- Process Development

- Injection Molding

- Post Injection Molding Services - assembly, kitting, packaging, and parts decoration

Do you have a part design that needs manufacturing support?

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.