PLASTIC PART DECORATION TO COMPLETE YOUR MANUFACTURING SOLUTION

Enhance branding, ensure compliance - all integrated with our injection molding services

Plastic part decoration plays a vital role in both product function and appearance, from clean, branded surfaces to durable markings required for traceability and compliance. These details matter, especially in high-performance sectors like medical, defense, pharmaceutical, and industrial manufacturing.

Keeping these post-molding services under one roof ensures quality control, design integrity, and a seamless transition from molded part to finished product, all backed by the same engineering excellence we bring to every project.

To support our injection molding capabilities, Crescent Industries offers in-house part decoration services. Check these out down below⬇️

CRESCENT'S INJECTION MOLDED PART DECORATION METHODS

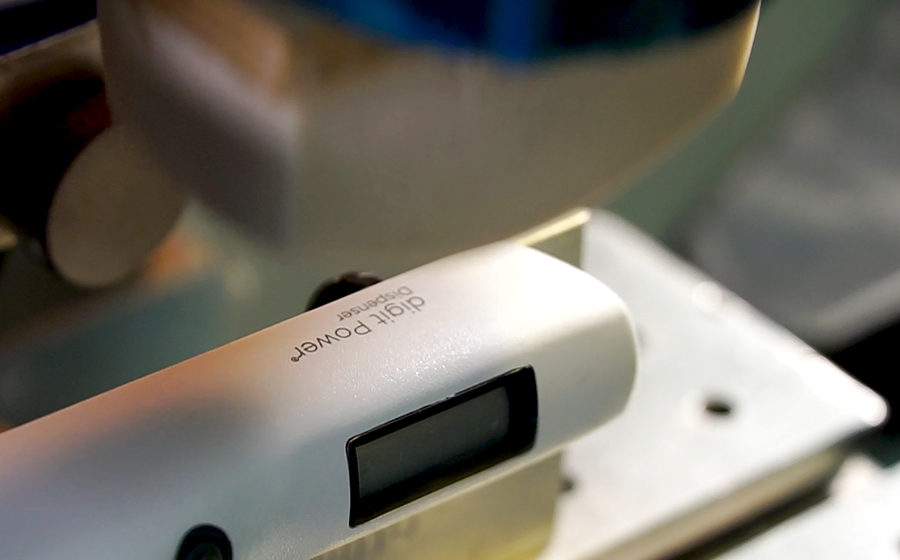

Pad printing involves a silicone pad picking up ink from a "negative" image of the design and transferring it to the part. Because the pad can meet the piece's shape, this process is ideal for rounded components, irregular surfaces, and complex shapes.

Laser marking oxidizes the plastic material just below the surface, applying a text or design while retaining a smooth finish. On the other hand, laser engraving removes a small amount of material at the surface, creating recessed text or design. And laser etching requires melting material and creating a raised mark on the product's surface.

Our high-speed, flatbed UV-Led inkjet printing process can provide high-resolution printing up to 1200 dpi and five colors on several parts at one time.

PLASTIC PART DECORATION BENEFITS & ADVANTAGES

AT cRESCENT INDUSTRIES

Consolidate Vendors

Incorporated in Your Project from the Start

Help Choose the Right Decorating Method

Reduce overall Production Time & Costs

One vendor performing these services eliminated the need to ship product from vendor to another, reducing your overall time and cost as well as maintaining risk. In additon, Crescent uses strategies like Focused Factory Work Cells and automation to perform part decoration operations to reduce lead time and increase throughput.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.