The History of Crescent Industries

1930S

Frank B. Paules, founder of Crescent Industries, learned his trade as a journeyman toolmaker at Pennsylvania Tool Company of York, PA. The Great Depression devastated Penn Tool, and massive layoffs occurred, including Frank. He eventually landed a job at American Insulator Company in New Freedom, PA, as a toolmaker manufacturing thermoset and thermoplastic molds, fixtures, and jigs. He earned the respect of his peers and supervisor and was quickly promoted to Research & Development Engineer.

1940s

Summit Machine Works obtained military contracts for machine gun turret and helm column castings for the famous PT gunboats during World War II. Most military work dried up by the war's end, and their future looked bleak. His business partner backed out, so Frank steered the company into another direction. This was when the Paules family renamed Summit Machine Works to Crescent Industries. This change signified a new beginning!

1950s

In 1956, Crescent Industries became Incorporated! Two years later, tragedy struck with the sudden passing of Frank Paules at the age of 51. The family rallied to preserve the business. His son Dean moved his young family and left his electronics career to join the company. Youngest son Daryl, after graduating from Johns Hopkins, joined as well.

1960S

In need of tool makers, Crescent established differential aptitude tests to hire young apprentices to become top-rated accredited journeymen mold makers. Over 30 apprentices have been trained in Crescent’s PA Approved Apprentice Training Program. In the late 1960s, Crescent purchased an old Watson/Stillman injection molding press. Dean applied his electronics ingenuity and led the fledgling molding department in reconditioning the machine. Crescent started to sample molds before shipment, making them one of the first shops to sample new molds!

1970s

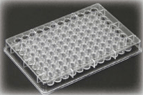

This was a pivotal decade. Crescent purchased a Natco 225 Ton, 14 ot several 4-cavity, 96 well diagnostic Microtiter plate molds, and started running production of these parts. This was the beginning of Crescent manufacturing products for the Medical Industry.

1980S

The front street location needed additions for their new molding venture. They purchased four 220-ton presses and four VanDorn 75-ton presses. Their first piece of automated equipment was also installed.

1990s

1996, the 50,000-square-foot cannery warehouse was purchased from the New Freedom Business Park. This building was completely renovated to a state-of-the-art molding plant and warehouse. This project was completed and placed into service in 1998.

2000S

In 2001, Crescent considered selling to a larger parent company but decided to execute an Employee Stock Ownership Plan (ESOP) instead. ESOP ownership allowed employees to share in the company's growth while allowing the Paules family to retain control. Eight years later, Crescent extended its manufacturing capabilities with another facility to accommodate Crescent Medical Plastics Division, followed by achieving ISO 13485:2003 Certification.

2010s

Crescent continues reinvesting and renovating its facilities to optimize its environments for its customers. They purchased their first set of Baxter robots, which sent them down the path of investing deeper into highly automated equipment for their processes.

.jpg?width=1200&length=1200&name=Crescent%20Team%202021%20(1).jpg)

2020S

Crescent celebrates its 75th Anniversary!

Completion of our new cleanroom facility and office space in New Freedom, PA

1930s

Frank B. Paules, founder of Crescent Industries, learned his trade as a journeyman toolmaker at Pennsylvania Tool Company of York, PA. The Great Depression devastated Penn Tool, and massive layoffs occurred, including Frank. He eventually landed a job at American Insulator Company in New Freedom, PA, as a toolmaker manufacturing thermoset and thermoplastic molds, fixtures, and jigs. He earned the respect of his peers and supervisor and was quickly promoted to Research & Development Engineer.

1940s

Summit Machine Works obtained military contracts for machine gun turret and helm column castings for the famous PT gunboats during World War II. Most military work dried up by the war's end, and their future looked bleak. His business partner backed out, so Frank steered the company into another direction. This was when the Paules family renamed Summit Machine Works to Crescent Industries. This change signified a new beginning!

1950s

In 1956, Crescent Industries became Incorporated! Two years later, tragedy struck with the sudden passing of Frank Paules at the age of 51. The family rallied to preserve the business. His son Dean moved his young family and left his electronics career to join the company. Youngest son Daryl, after graduating from Johns Hopkins, joined as well.

1960s

In need of tool makers, Crescent established differential aptitude tests to hire young apprentices to become top-rated accredited journeymen mold makers. Over 30 apprentices have been trained in Crescent’s PA Approved Apprentice Training Program. In the late 1960s, Crescent purchased an old Watson/Stillman injection molding press. Dean applied his electronics ingenuity and led the fledgling molding department in reconditioning the machine. Crescent started to sample molds before shipment, making them one of the first shops to sample new molds!

1970s

This was a pivotal decade. Crescent purchased a Natco 225 Ton, 14 ounce modern injection molding press, built several 4-cavity, 96 well diagnostic Microtiter plate molds, and started running production of these parts. This was the beginning of Crescent manufacturing products for the Medical Industry.

1990s

1996, the 50,000-square-foot cannery warehouse was purchased from the New Freedom Business Park. This building was completely renovated to a state-of-the-art molding plant and warehouse. This project was completed and placed into service in 1998.

2010s

Crescent continues reinvesting and renovating its facilities to optimize its environments for its customers. They purchased their first set of Baxter robots, which sent them down the path of investing deeper into highly automated equipment for their processes.

Crescent also achieved FDA Registration in 2014.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.