WHEN EXPERIENCE COUNTS, COUNT ON CRESCENT INDUSTRIES

what you get with our experience

For more than seven decades, Crescent Industries has led the way by offering Design for Manufacturing (DFM), new injection mold builds, injection molding process development, and manufacturing of precision injection molded parts and devices.

We offer single-source, reliable, and time-tested solutions that meet our customers' specific needs. Over the years, our team has earned a reputation for being a long-term strategic partner. For some, it has been over 35 years.

The Solutions We Offer

With extensive experience and a deep understanding of all facets of injection molding, from mold design to new mold builds and manufacturing, Crescent Industries guarantees the highest quality and value in our products. Our customized mold solutions are designed to meet our customers’ exact needs.

As an employee-owned company, we proudly provide these injection molding solutions.

Plastic Injection Mold Design

Utilizing our Design for Manufacturing (DFM), 3D modeling, and mold flow analysis strategies, we start with the end goal in mind – mold designs that lead to ease of manufacturing, efficient production methods, and cost effectiveness.

Want to see some or our engineering services at work?

Build New Injection Molds

Crescent Industries' Injection mold building experience and capabilities are unmatched in the industry. Our team of dedicated project managers, engineers, and mold designers work closely with our customers to achieve the desired product outcomes.

We have extensive experience with complex mold geometries and design features. Our capabilities allow us to produce a vast array of mold types.

Curious about the many types of molds we have built?

Custom Injection Molding

Over the years, we have served and continue to serve the medical, pharmaceutical, defense, and industrial markets where precision manufacturing is demanded. Regardless of volume or scale, our team is a strategic, long term partner that can be relied upon to consistently perform up to the highest standards. This includes custom injection molding in our brand new certified ISO 7 cleanroom facility.

We also specialize in insert molding and overmolding and other tailor-fit services. Crescent Industries also has extensive experience successfully moving tools to our facility for production.

Wondering about what custom injected molding projects we have done?

Post Processing Operations

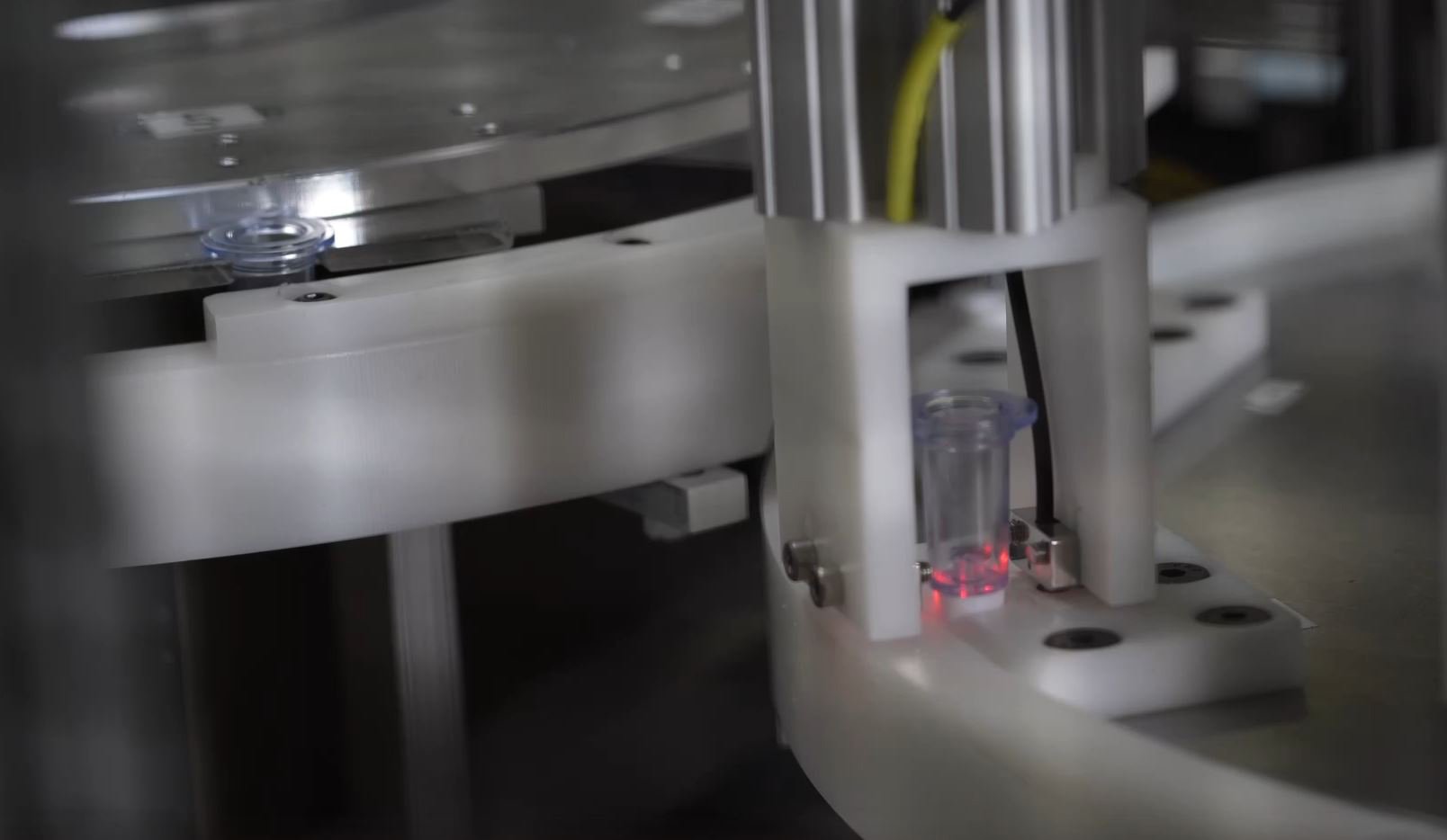

Crescent Industries provides expert, start to finish, solutions by offering post-processing operations. Our services include assembly, sub-assembly, kitting, part decoration, and packaging operations to complete the components and devices we mold.

Whether your molding needs are simple or complex, our post processing services can be completed either by our team of highly skilled employees, or via in-house robots and automation tools. We have decades of assembly experience with adhesive bonding, UV bonding, ultrasonic welding, and mechanical fastening.

Medical device assembly can be performed in the general molding area, or in our on-site, recently expanded new ISO 7 cleanroom facility.

Want to see our one stop manufacturing solution in action?

curious to see the role automation plays in our daily operations?

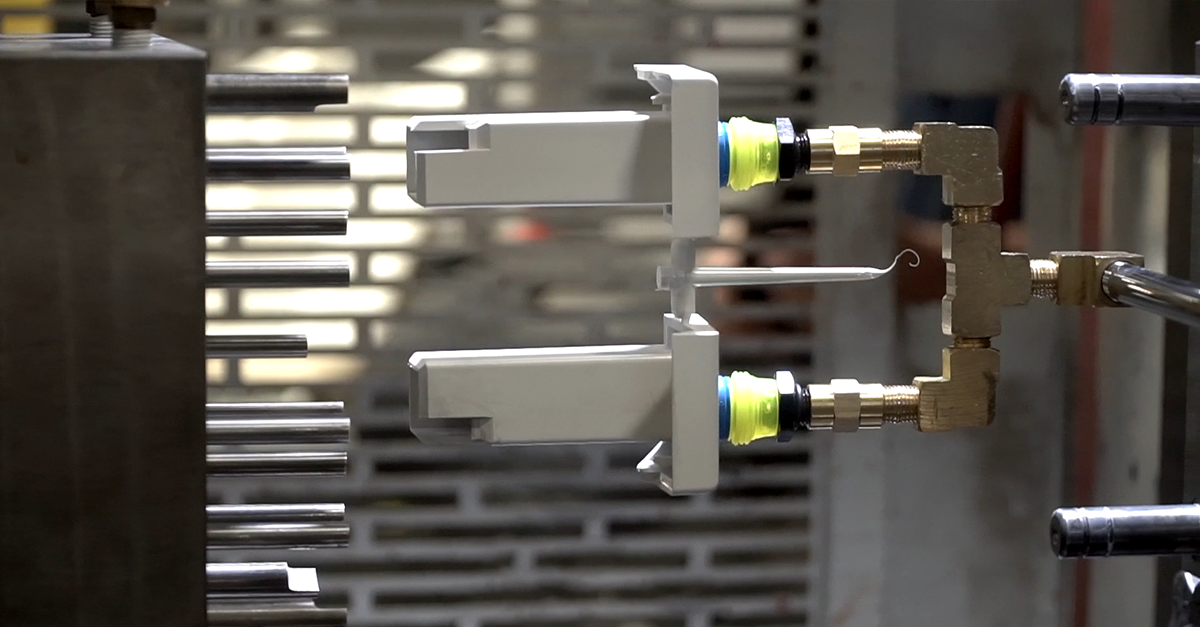

Our in-house injection molding automation team creates custom solutions to match your project needs. The Crescent Industries team uses End of Arm Tooling (EOAT), Collaborative Robots, and Automated Work Cells to maximize efficiency and product precision.

The many benefits of our injection molding automation solutions include a significant reduction in rejected parts, lower labor handling and overall production costs, and optimized injection molding throughput.

Quality is Job # 1

Our highly knowledgeable and experienced team of engineers and technicians are dedicated to producing the highest quality devices and components, that meet our customers’ exact needs.

We are proud to hold the following credentials and offer these capabilities:

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.