Custom PLASTIC PARTS

AT crescent industries...

We take pride in being a leading provider of high-quality custom molded components and devices. With our three manufacturing facilities in New Freedom, PA, extensive experience, and commitment to excellence, we are dedicated to helping you bring your innovative ideas to life.

Our team works closely with you to streamline your production process. Starting with Design for Manufacturing (DFM) support through final assembly and packaging, we can manage every step of the journey for you.

Our experience includes various thermoplastics, engineered resins, and elastomers, allowing us to produce the plastic components or devices you need. Even if you need specialized injection molding services like insert molding, overmolding, cleanroom molding, or are looking to move your existing injection mold tooling to another vendor, we are here to help YOU.

A strategic partner committed to your success

We understand that each project is unique, and that’s why we offer customized solutions tailored to your specific requirements. Whether you need low or high-volume production, we have the flexibility to accommodate projects of any scale.

- 75+ Years of Industry Experience

- In-House Mold Design & Tool Building

- Develop a Robust Molding Process

- Focus Factory Work Cells

- Industry 4.0 Press Monitoring

- Post-Processing Operations (Part Decoration, Assembly, Kitting, and Packaging)

- In-House Automation Team

- ISO 13485:2016, ITAR

The Markets We Serve

We've been shaping these market segments for 75+ years. Our quality management system and certifications are specifically tailored to these markets, including ISO 13485 certification and ITAR registration.

-

Medical & Pharmaceutical

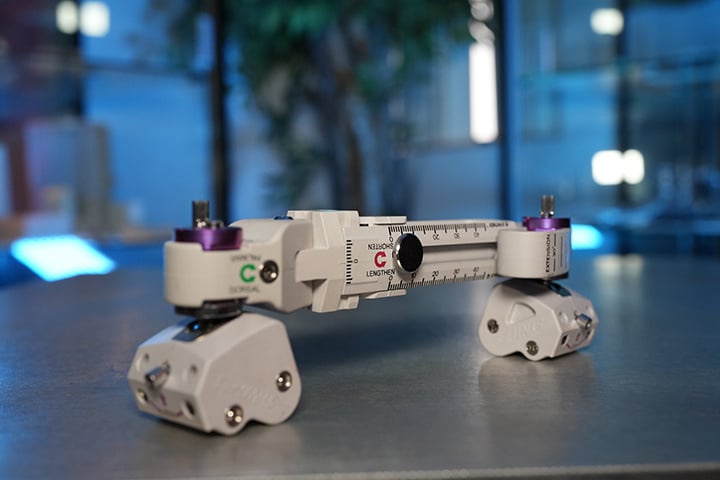

Explore Our Medical Molding ExpertiseWe specialize in manufacturing Class I, II, and III components and devices, utilizing a wide variety of medical grade resin materials.

-

Military & Defense

Recognized as an ITAR-Registered Manufacturer by the U.S. State Department, we have decades of experience in the defense industry. Currently our CMMC SRRS score is 84, working towards 110 CMMC 2.0 regulations with regard to preventing, detecting, and responding to cyber threats.Discover Our Military-Grade Solutions -

Industrial & OEM

With a tonnage capacity of 11 tons to 450 tons, as well as an unmatched level of vertical injection molding expertise, we develop custom product solutions for a wide range of diverse industries.Precision Molding for Complex Parts

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.