Overmolding Plastic Parts

Overmolding at Crescent

Welcome to Crescent Industries, where we specialize in providing high-quality overmolding services that complement our injection molding capabilities, giving you a comprehensive range of options. Our team of experienced professionals is dedicated to delivering exceptional results that meet or exceed your expectations.

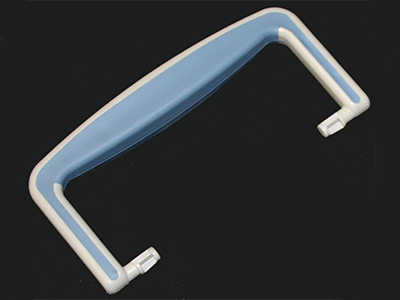

The overmolding process involves combining two or more plastic materials to create a single, integrated part.

These techniques are used to add these typical features and to increase the products:

- Grips

- Texture

- Color

- Ergonomics

- Durability

- Impact Resistance

- Weatherability

Overmolding process

At Crescent Industries, we use state-of-the-art equipment and processes to ensure that your overmolded parts are of the highest quality. Including vertical/vertical injection molding presses, using gravity to hold the substrate in place during the overmolding process.

Our team of experts can provide design assistance to help you optimize your product for overmolding. We use advanced software to simulate the overmolding process and ensure your design is production-ready. (provide a link to plastic injection mold design page)

CRESCENT'S OVERMOLDED PLASTIC PARTS

We have extensive experience working with a variety of materials, including thermoplastic elastomers (TPE) and thermoplastic urethanes (TPU), to provide that soft rubber-like feel. Typical Applications:

- Surgical devices

- Handheld devices

- Buttons

- Handles

- Knobs

- Cover Corners

- And more.

The Markets We Serve

-

Medical & Pharmaceutical

Learn MoreWe specialize in manufacturing Class I, II, and III components and devices, utilizing a wide variety of medical grade resin materials.

-

Military & Defense

Learn MoreRecognized as an ITAR-Registered Manufacturer by the U.S. State Department, we have decades of experience in the defense industry.

Crescent Industries is fully compliant with NIST regulations with regard to preventing, detecting, and responding to cyber threats.

Working with various military and defense grade resins and materials, we manufacture a variety of precision and highly durable components that meet the highest standards for mission critical applications.

-

Industrial & OEM

With a tonnage capacity of 50 tons to 385 tons, as well as an unmatched level of vertical injection molding expertise, we develop custom product solutions for a wide range of diverse industries.Learn More

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.