TOOL TRANSFERS BUILT FOR LONG-TERM SUCCESS

ensure production-ready molds with crescent industries

Transferring your injection mold tooling is a significant decision. At Crescent Industries, we understand the complexities involved and prioritize a comprehensive mold evaluation to ensure your tools are production-ready.

Our experience shows that many transferred tools, especially from overseas, may not meet the rigorous demands of production and quality.

WHY MOLD EVALUATION IS ESSENTIAL

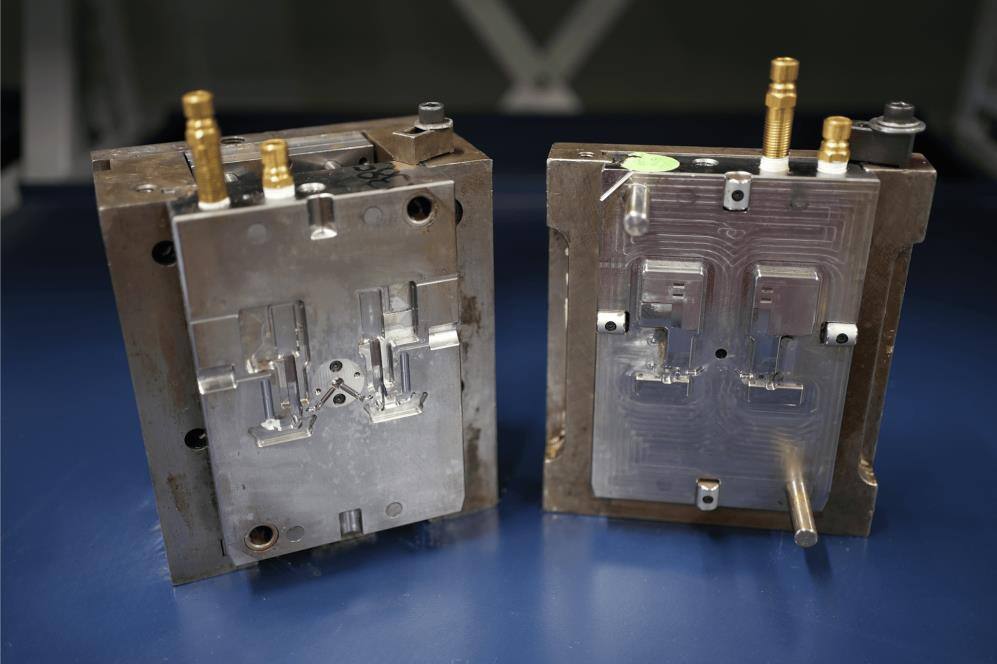

Before accepting any tool transfer, we conduct a thorough evaluation to assess:

- Material Integrity: Verifying steel type and hardness to ensure durability

- Design Compatibility: Assessing mold flow, cooling systems, and gating to match production requirements

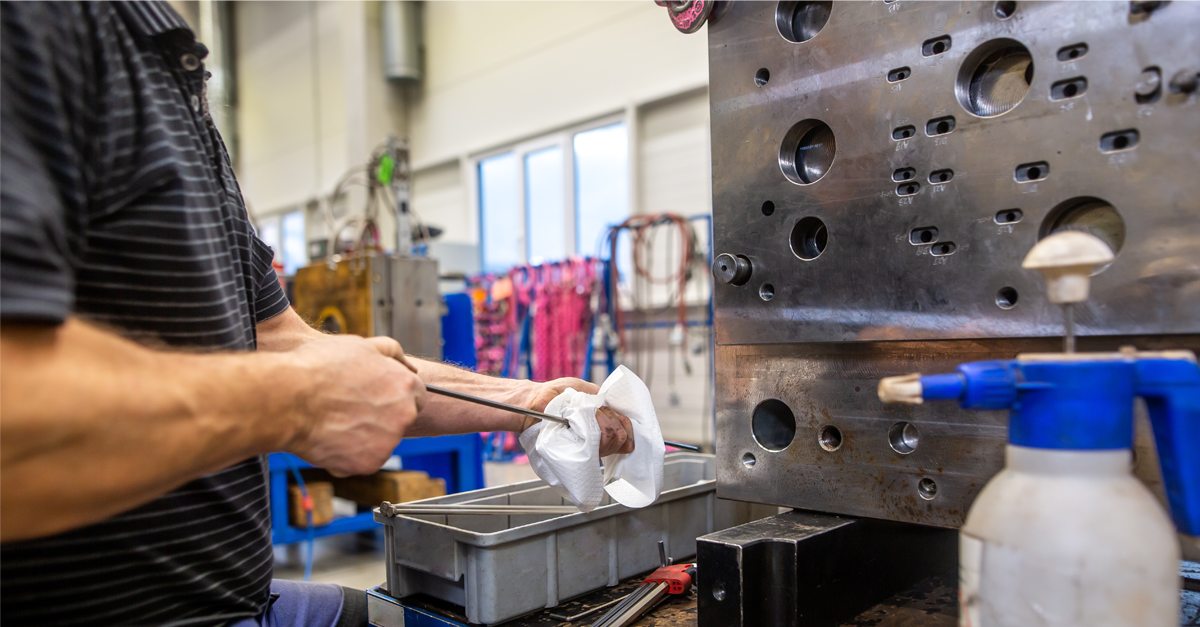

- Tooling Condition for Operational Readiness: Checking the tooling for wear, broken components, requirements for metric to standard conversion of components, maintenance history, and potential need for refurbishment.

This proactive approach ensures that your tooling meets industry standards and aligns with your production goals.

CRESCENT'S PROVEN TOOL TRANSFER PROCESS

With over 560 successful mold transfers and support for more than 600 custom injection molded parts, our process includes:

- Initial Consultation - understanding your specific needs and concerns

- Comprehensive Mold Evaluation - detailed assessment of the tool's condition and suitability

- Strategic Planning - developing a tailored plan for refurbishment, replacement, or maintenance if needed, including potentially running at-risk production to avoid a line-down situation

- Seamless Integration - using our in-house tooling facility, journeyman mold builders, and ERP system to ensure a smooth transition

- Validation and Production - conducting tooling capability studies, performing FAIRs, and achieving validation requirements swiftly to minimize downtime

Our systematic approach minimizes disruptions and ensures continuity in your supply chain.

"Due to circumstances beyond our control, we had to move 47 tools. The components of these molds supported millions of dollars a month in medical devices sales. We were afraid that we would go into backorder, losing sales and customers. After meeting with several respected molders we decided to transfer these molds to Crescent. We're so glad we did! Demonstrating across-the-board competencies, they managed every aspect of the project, taking the worry off our hands. I was particularly impressed with the robustness of their Quality systems. Quicker than we could have hoped, they had our molds inspected, sampled, and validated. Our production hardly missed a beat."

Get the tool transfer checklist

We developed a tool transfer checklist for you to understand the information your injection molder might request when transferring your tools to a new vendor.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.