CASE STUDY

Crescent Industries Delivers a Win by Offering a Full Service Cleanroom Injection Molding Solution

CASE STUDY

Deciding to switch product or material vendors in the medical device manufacturing market is never an easy feat. But when done correctly, the outcome can have far more benefits than the company originally imagined.

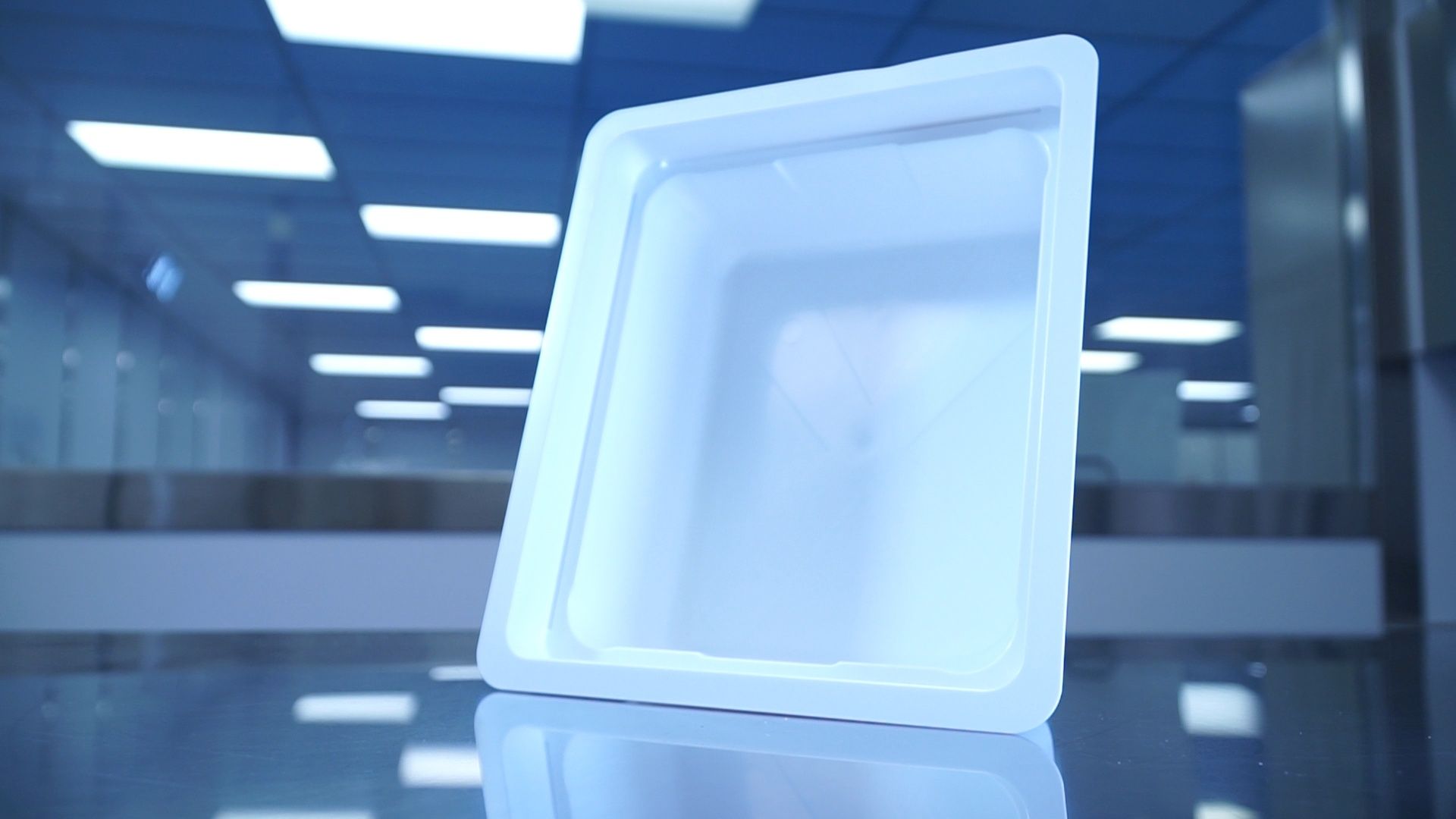

This was certainly the case for one large pharmaceutical packaging company based in North America that chose to work with Crescent. The company wanted to switch vendors for their new injection molded tub used for sterilizing, filling, and shipping ready-to-use (RTU) containers.

The injection molded tub is the anchor for this company’s RTU platform. Various types of containers — vials, cartridges, and syringes — are secured in packaging and then contained using this standardized tub as they process through flexible filling and syringe filling lines. Needless to say, the tub’s standardization of dimensions and sterility are vital to its ability to be compatible with equipment from multiple vendors.

Problem: Streamline Manufacturing Process for Plastic Part

Crescent’s promise to provide free truck deliveries for customers anywhere within 100 miles meant this company could eliminate the need for a third-party transportation carrier. While this service is a major perk, by the time this project was complete, Crescent proved valuable for a plethora of other reasons far beyond geographic proximity

-

Solution: Purchased Major Capital Investments

When Crescent sets out to provide value for its customers, not much will get in the way of their problem-solving commitment.

Crescent has both a general molding facility and a certified ISO 7 cleanroom manufacturing facility that uses scientific injection molding principles, state-of-the-art injection molding machines and automated quality inspection equipment. Even with its state-of-the-art facilities, molding the company’s tub required larger press than Crescent currently had. Without hesitation, Crescent invested in a new, higher-tonnage injection molding press to tackle this large project. -

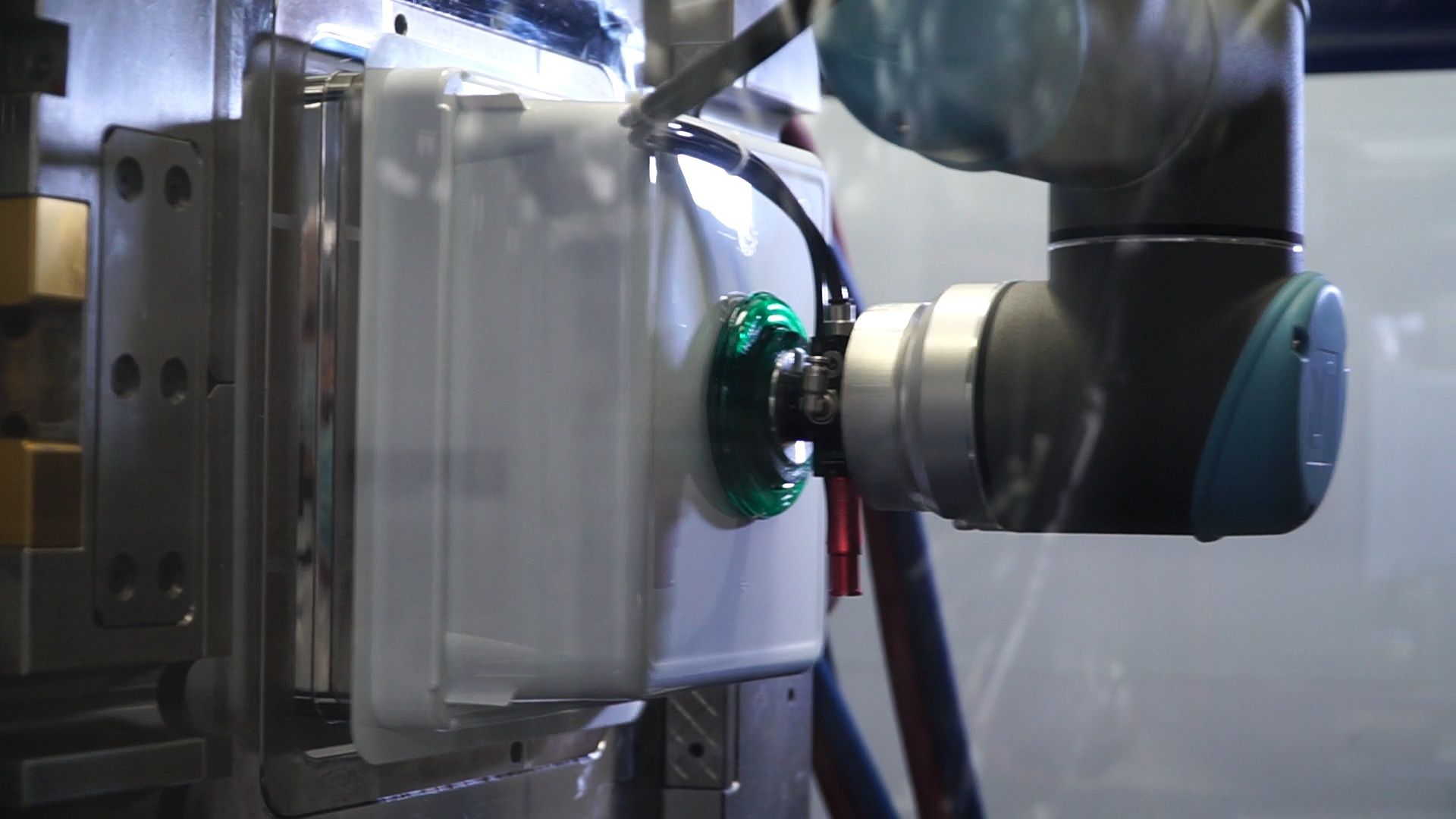

Help from Cobots

Crescent purchased their new cobot specifically to remove the molded tubs from the mold and place them on conveyor for packaging. This investment meant less human handling during the molding process, decreasing both bio-burden and the risk of contamination. The application of the tubs — housing containers filled with medicine to be used directly by patients — meant cleanliness was a top priority.

Once the tubs were removed from the press, Crescent’s cobot stacked them onto the conveyor. Once enough tubs were stacked, the conveyor moved to its next position to prepare for another stack. Then, the stacks of tubs were packaged and ready for customer delivery. -

Resin Material Improvement

These tubs naturally attract particles due to static electricity. To help minimize this, Crescent took the customer’s material requirements to Crescent’s usual resin distributor. The distributor recommended adding an anti-static component.

Crescent knew that adding an anti-static to the tub's usual resin could not alter the finish color of the tubs. Crescent took advantage of their resin supplier’s compounding expertise and had them add both the anti-static additive and the colorant needed to match the color of the usual tubs.

This move again streamlined production for the customer by consolidating the resin manufacturing and colorant into one vendor. At the same time, Crescent decreased the amount of handling the resin would undergo and reduced the likelihood that finished tubs would come in contact with contamination or foreign substances. Or course, before moving forward with the production of this new resin compound, Crescent checked with the customer for approval.

-

Injection Mold Improvement

Crescent’s innovation didn’t stop with rethinking the resin. By leveraging its in-house mold design and revision expertise, Crescent also made improvements to the tooling to reduce flash at the parting line on the molded tubs. This resulted in the current single-cavity, Class 101, hot-runner mold. -

Results: A Complete Injection Molding Solution

Through its commitment to providing more value and exceeding customer expectations, Crescent was able to streamline this large pharmaceutical packaging company’s molding process in a way they hadn’t imagined possible.

What started as a vendor change due to the convenient location turned into working with a vendor that purchased new capital equipment, implemented a resin material upgrade, improved existing molds, and combined cleanroom manufacturing injection molding facilities with in-house automation and design teams. All of these value-adds worked together to reduce the risk of contamination and enhance the tub mold production process overall.Better yet, Crescent’s high-throughput cleanroom manufacturing guarantees that this customer will be able to meet the increasing demand for this tub over the next few years. Crescent's investments to improve this tub makes it possible for this product — and others like it — to streamline RTU pharmaceutical filling lines. Such will help the medical industry, as a whole, meet current and future medical device demands. This is what working with an injection molding partner will do for you.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.