The reason for PFMEA's and control plans for plastic injection molding

Understanding PFMEAs and Control Plans

Product/Process Failure Mode and Effect Analysis (PFMEA) is a quality engineering tool used to quantify and evaluate the following analysis tasks:

- Identify critical input and process variables that can affect product quality

- Formulate assumptions about the relationships between variables that can affect product quality

- Evaluate the risk associated with product defects and mitigate that risk.

PFMEA is a structured approach to identifying, estimating, evaluating, and prioritizing risk.

A control plan is used to manage the process variables involved to reduce the risk of product defects in the molding process. For example, pressure and temperature are key variables that must be controlled throughout the molding process. Using PFMEA, pressure and temperature would be identified as critical process variables, their relationship to each other and their impact on the resulting product quality would be analyzed, and a control plan would be implemented to reduce the potential risk of product defects.

The goal of using these quality engineering tools is to improve product quality. However, it is important to first prioritize any quality control effort based on the relative risk involved.

Determining a Risk Priority Number (RPN)

The RPN is used to calculate the relative risk associated with defects. The formula for calculating the RPN is:

RPN = S (Severity) x O (Occurrence) x D (Detectability)

The RPN must be calculated for the entire process or design. After the RPN is calculated, the failure modes with the highest RPN are assigned the highest priority when corrective action is considered. It is important to note that the failure modes with the highest severity would not necessarily be addressed first. It is possible that less severe failures might occur more often and be less detectable, and therefore have higher RPN ranking than more severe failures.

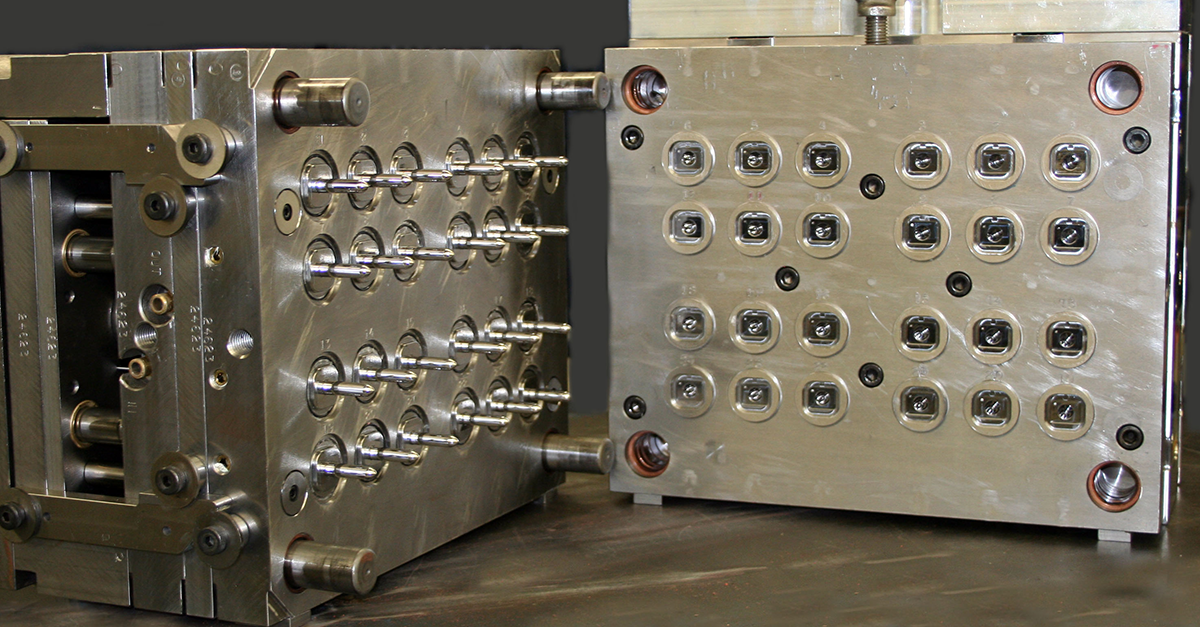

Applying Quality Control Engineering to Plastic Injection Molding

PFMEAs, Control Plans, and RPNs are used in injection molding to analyze the risk of failure for a design, implement a plan to control process variables and prioritize corrective action based on the relative risk of defects occurring within the process. Using this discipline has the potential benefit of reducing overall failure rates while requiring only targeted and specific corrective actions.

Today’s plastic injection molding projects can improve their overall quality and reduce failure rates through the consistent use of these quality control analysis tools.

Crescent Industries Inc. puts these practices to work to achieve optimal quality from design through final production for our customer's injection molded components.

Topics:

Related Articles

-

Oct 28, 2025

Injection Molding Compliance: Quality Validations Explained

Read MoreUnderstanding Quality Validations in Injection Molding

Precision and repeatability are the...

-

Feb 15, 2024

How to Ensure High Quality Injection Molding: 6 Best Practices

Read MoreThe widely used practice of injection molding is a highly versatile and efficient manufacturing...

-

Feb 01, 2024

Why Should You Work With an ISO 13485 Certified Injection Molder?

Read MoreIn medical device manufacturing, it's important to have a business partner who understands the...