What to Ask Before Choosing an Injection Molding Company

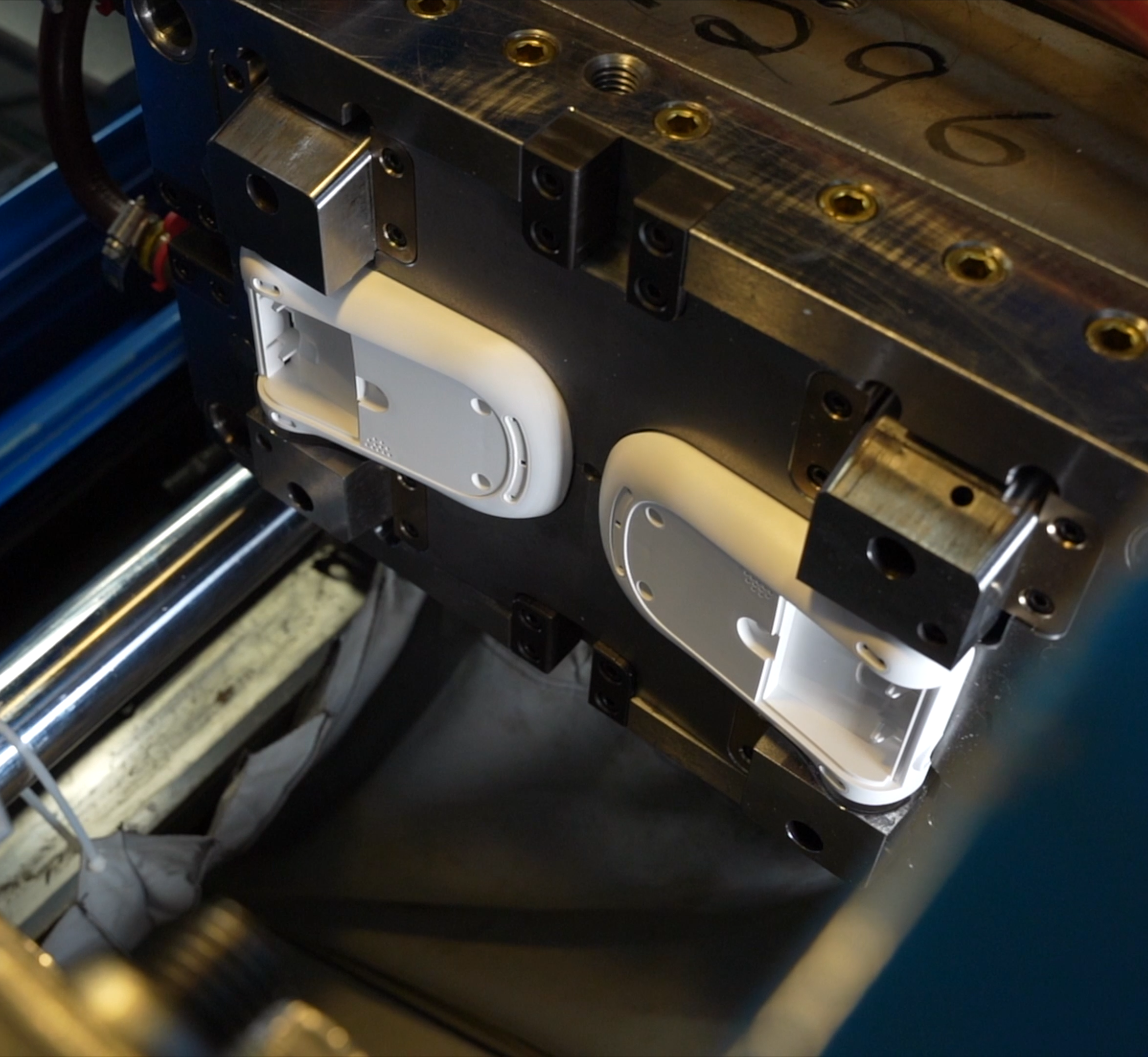

Injection molding offers a range of benefits to companies across various industries, including those producing medical devices, military equipment, and original equipment manufacturers (OEMs). When your organization is looking for the right plastic injection molding partner, however, there are a few questions to ask to ensure they will provide the level of service you’re looking for.

Choosing an injection molding partner can make or break your product’s success-especially in regulated markets like medical, pharmaceutical, and defense. Ask the right questions upfront, and you’ll save time, money, and future headaches.

Ensure They Can Handle Your Specific Needs

Every injection molding company will have unique focus areas and capabilities, but you need to make sure they can provide what you need. For instance, ensure they offer design for manufacturing support, build injection molds in-house, and have a process development strategy. Confirm the company will align with your needs by asking these key questions:

What Are Their Core Services and Specializations?

Closely assess the types of injection molding services they provide. What types of plastic products do they produce? What injection molding process do they use? What are their specialties? This initial review can tell you valuable information before you move forward.

Do They Have Experience in Your Industry?

Next is industry expertise. Is your industry listed on their website? What kinds of projects have they completed within that industry? You need a partner who knows the intricacies of your specific market and audience. Ensure the company has significant expertise in your industry, whether it is medical, defense, or industrial.

How Accessible and Responsive Are They?

Ask the company how they approach communication. What channels do they use? How quickly will they respond to an inquiry? Are they responsive? How will you reach out if you have a question? Communication is key to a successful partnership.

Verify Their Commitment to Quality Assurance

Next, ensure you receive the high-quality plastic products you’re looking for. Even if a company touts low prices, that doesn’t always mean they will deliver the product quality standards that you and your market require. It’s crucial to ensure they stay compliant with their certifications and standards. For example, in medical molding, look for ISO 13485 certification, and in defense, ITAR registration is often required. The following questions focus on quality assurance:

What Are Their Quality Control Measures?

The company you choose needs to have a stringent quality control process in place that ensures consistency and value. This is key so that your production requirements are met without worry or errors. Measures should include inspection processes throughout each stage of production, data collection, and equipment evaluations. Asking for quality standards gives you peace of mind that you’re on the same page.

Can They Provide Samples or References?

The best way to get reassurance about an injection molding company is to hear from past customers and view actual past results. Request samples of the products you need from past projects. Ask for references so you can contact former or current customers about their experience with the company. If a company isn’t willing to provide these materials, it could be a red flag.

Look for Deep Industry Expertise and Services

Your products require the latest technologies for optimal manufacturing. The best injection molding company for you will embrace these innovations in the software and equipment they use. Ask these questions when evaluating injection molding companies:

What Technology Do They Use?

Automation plays a crucial role in today’s production processes. Ask each company if they rely on this technology, and how. What other tech resources set them apart from competitors? What is their approach to keeping up with upgrades and new technologies? How often do they review their current systems?

Do They Offer Design Support or Engineering Expertise?

The right plastic injection molder will have a wide range of expertise that they can offer you. Key services are design support and engineering guidance. These areas will ensure that your end results are exactly as you want them, of high quality, and created through an efficient manufacturing process.

Understanding Cost and Timelines

Beyond experience, technology, and quality, you also need to know the logistics. Cost and expectations for speed and timeline are just as important. Focus on this set of questions to ensure you’re agreeing to terms that work for you:

What Are the Pricing Structures?

The best-case scenario is a company that is upfront about how much its services cost. Ask them how pricing works and when you’ll be charged. Analyzing cost and understanding the company’s pricing model are key factors in determining long-term alignment.

What Is Their Lead Time for Projects?

Every project could look different, as each has varying volume, requirements, and needs. However, the company should be able to provide you with an idea of their lead time for projects. Knowing their timing helps you manage your own timeline, and being clear about this from the outset helps manage expectations for everyone. You also want to be sure that you can realistically work with their projected lead time.

Partner With the Right Injection Molding Company Today

The right plastic injection molding company should align with your quality standards, cost requirements, and capability needs to ensure your products are exactly as you want them. Ask plenty of questions when searching for the right partner so you know the injection molding process will run smoothly and produce high-quality results.

The experts at Crescent Industries provide engineering capabilities, mold design process, tooling, custom injection molding, post-processing services, and automation to help you streamline your production needs. We have the ability to handle both high and low production volumes, and our quality standards enable us to consistently produce stunning products through repeatable processes.

Ready to get expert guidance tailored to your industry? Discuss with our team how Crescent supports the complex medical, defense, and industrial mold building and molding needs – with precision, speed, and reliability.

FAQs:

Q: What makes a good injection molding company?

A: Look for in-house tooling, industry-specific certification and experience, injection molding process development, DFM, and strong communication.

Topics:

Related Articles

-

Jan 14, 2026

Shortlisting U.S. Injection Molding Partners for Regulated Industries

Read MoreThe U.S. injection molding industry accounted for $42.85 billion in revenue in 2022 and is expected...

-

Sep 23, 2025

Injection Molding Project Management in Regulated Industries

Read MoreThe High Stakes of Injection Molding in Regulated Industries

Medical device and defense markets...

-

Jun 18, 2025

A Proven process for transferring your injection mold tooling with confidence

Read MoreTransferring or moving an injection mold is necessary sometimes especially in regulated and...