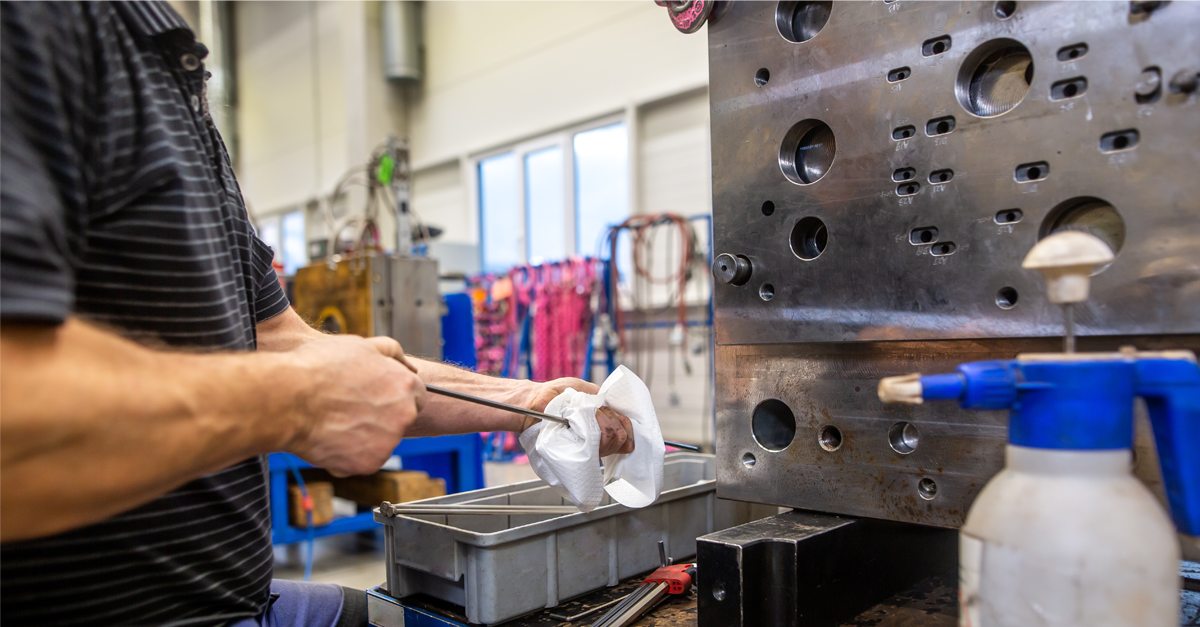

A Proven process for transferring your injection mold tooling with confidence

Transferring or moving an injection mold is necessary sometimes especially in regulated and high-performance industries like medical and defense products. It’s often feels daunting and high-risk, but it doesn’t need to be – the process starts with a proper tool evaluation.

At Crescent Industries, we’ve helped hundreds of our OEMs and device manufacturers safely transfer tooling into our facility. And in many cases – especially with overseas-built tools-we uncover problems that could have derailed production timelines or validation efforts if left unchecked.

This article explores the top risks of injection mold tool transfers and how to ensure your tooling supports long-term production success in your most critical applications.

The Reality: Many Transferred Tools Aren’t Ready for Production

In precision-driven industries, products must meet stringent performance and quality standards, requiring documentation. However, molds from overseas or unvetted suppliers often fall short in areas like:

- Steel Materials Used – soft or misidentified materials reduce tool life and repeatability

- Cooling Design – poor thermal management affects part consistency and cycle times

- Gate/Vent Design – impacts dimensional accuracy and cosmetic quality

- Validation Gaps – lack of documentation or unable to produce approved first articles for validation

For medical device components, even minor issues can delay a launch or trigger the need for rework. In defense manufacturing, poor mold performance can breach tolerances and disrupt mission critical supply chains.

Mold Evaluation: The First Step in a Secure Tool Transfer

At Crescent Industries, we never take a transferred tool at face value. We perform a comprehensive mold evaluation before accepting a tool into production – especially those built offshore or by molders not versed in the medical, defense, or complex molding.

Crescent’s Evaluation includes:

- Material and steel type verification

- Cooling, gating, and ejection system assessment – if overseas, this includes converting from metric to standard

- Tooling component wear and preventative maintenance history

- Tolerance capability review based on product specifications

- Automation and mold press compatibility

This upfront assessment protects your investment and ensures that your injection mold can reliably support your production needs, whether for medical device enclosures, overmolded surgical tools, or military battery packs.

What if the Tool Isn’t Ready?

Our customers appreciate that we provide honest, engineering-backed options after every evaluation. You’ll receive a clear, actionable plan:

- Proceed to production (if the tool passes evaluation)

- Refurbish the tool in-house

- Recommend replacement or rebuild to meet long-term goals

Because Crescent has an in-house tooling facility staffed with journeyman mold builders, machinists, and mold design engineers ensures you have a team of experts caring for your tooling asset.

When to Consider Moving Your Injection Mold Tooling

Are you facing these challenges:

- A supplier shutdown or quality breakdown

- Rising costs from overseas logistics

- Poor communication

- The need to scale up production or automate production

- Increased regulatory pressure requiring validation-ready partners

In these cases, a tool transfer can make sense – but only when guided by engineering, injection mold tooling experience, and process discipline.

Protect Your Project. Start with an Evaluation

If you’re responsible for producing medical devices, military-grade components, or complex parts, don’t leave your tooling to change. Whether reshoring from overseas or transitioning from an existing supplier, a mold evaluation is your first step for product life production.

See how Crescent facilitates tool transfers for you.

At Crescent Industries, we follow a proven, structured approach to every mold tool transfer—starting with a comprehensive in-house evaluation. Our cross-functional team of engineers, toolmakers, and quality specialists assesses each mold for material integrity, design accuracy, production readiness, and compliance with regulatory standards. From initial inspection through any necessary rework, all processes occur under one roof, ensuring speed, traceability, and quality control at every step.

👉 Explore Crescent’s Tool Transfer Process

Topics:

Related Articles

-

Jan 14, 2026

Shortlisting U.S. Injection Molding Partners for Regulated Industries

Read MoreThe U.S. injection molding industry accounted for $42.85 billion in revenue in 2022 and is expected...

-

Sep 23, 2025

Injection Molding Project Management in Regulated Industries

Read MoreThe High Stakes of Injection Molding in Regulated Industries

Medical device and defense markets...

-

Jun 18, 2025

A Proven process for transferring your injection mold tooling with confidence

Read MoreTransferring or moving an injection mold is necessary sometimes especially in regulated and...