Choosing the Right Mold Cavitation for Injection Molding Success

OEMs Face a Critical Manufacturing Decision

Original equipment manufacturers (OEMs) are under constant pressure to balance production volumes, cost control, and product quality. One of the most impactful decisions in this equation is selecting the right mold cavitation strategy for injection molding. This decision affects everything from lead time and speed to market to cost-per-part and overall tooling investment.

What Is Mold Cavitation?

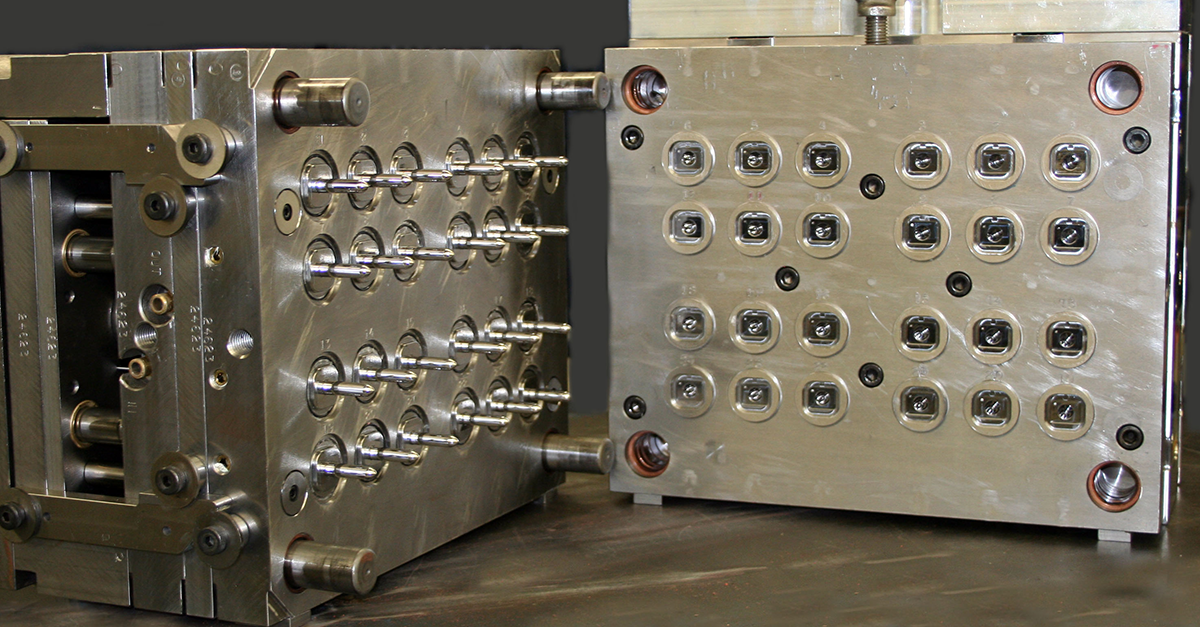

Tool cavitation refers to the number of cavities—or impressions—within an injection mold. A mold with a single cavity produces one part per cycle, while a multi-cavity mold can produce anywhere from two to over 200 parts in a single molding cycle.

Single Cavity Mold = 1 part per cycle

Multi-Cavity Mold = Multiple parts per cycle

How Many Cavities Does Your Mold Need?

This is one of the most important design decisions you'll make. While there’s been a shift toward higher cavitation molds to drive down costs, high cavitation isn't always the best fit for every application. Below are key factors to guide your decision-making process.

1. Initial and Ongoing Costs

- Initial Tooling Cost: Single cavity molds are typically less expensive to design and build.

- Ongoing Operating Cost: Multi-cavity molds reduce the cost-per-part by increasing output and reducing machine time and labor.

- Maintenance & Equipment: Higher cavitation molds may require larger machines and more frequent maintenance.

💡Tip: Request a detailed cost analysis to compare the total cost of ownership for both low and high cavitation options.

2. Production Volume Requirements

If your part requires medium to high volumes, a multi-cavity mold may offer the best ROI. Producing more parts per cycle:

- Speeds up production timelines

- Reduces the need for multiple machines

- Avoids scheduling conflicts across machines

3. Lead Time Considerations

Need to move fast? Single cavity molds often come with shorter lead times and faster ramp-up to production—ideal for prototyping or when speed-to-market is critical.

4. Part Complexity and Design Changes

Parts with tight tolerances, intricate features, or frequent design updates benefit from lower cavitation tools. These molds offer:

- Easier validation and adjustment

- More flexibility for revisions

- Better quality control on complex geometries

5. Inventory Strategy

High cavitation molds can generate extra inventory, which can be a plus for high-demand or seasonal products. Stockpiling fast-moving parts helps avoid costly production delays during demand spikes.

6. Prototyping vs. Final Production

For prototype parts, a single cavity mold minimizes costs and accelerates time to first article approval. Once your part design is finalized, consider transitioning to a multi-cavity mold for full-scale production.

Why Choose Crescent Industries for Tool Design and Mold Cavitation Strategy?

Crescent Industries is your trusted partner in navigating injection molding complexities. We collaborate closely with our customers to evaluate:

- Application-specific production goals

- Total project evaluation

- Quality and speed-to-market needs

Whether you're producing high volumes or refining a prototype, our experienced team helps you select the optimal mold cavitation strategy to achieve your goals.

Let’s Talk About Your Next Tooling Project

Have questions about how many cavities your mold should have? We’re here to help!

👉 Contact Crescent Industries today to speak with our tooling experts.

Topics:

Related Articles

-

Oct 08, 2025

Medical Device Cleanroom Manufacturing: Plastic Injection Molding

Read MoreWhy Cleanroom Manufacturing Matters for Medical Devices

Medical devices are subject to strict...

-

May 12, 2025

The Role of Hot Runners in Injection Molding

Read MoreBefore the invention of hot runner systems, manufacturers used cold runner injection methods. These...

-

Apr 23, 2025

How Long Does an Injection Mold Last? | Durability Factors

Read MorePlastic injection molds can manufacture custom parts in numerous industries with great accuracy and...