The Difference Between a Dedicated Injection Mold vs a Toolset

The high quality injection mold tools needed to produce precision plastic parts can be costly. One approach that can mitigate this expense is purchasing an injection mold toolset, if project requirements allow for it. You'd only need to purchase the heart of the tool and not all the mold components.

However, it may not always be the most suitable option. In such cases, investing in a dedicated injection mold yields the best product results.

Here's an in-depth look at what to consider when choosing between using a toolset in a pre-made master frame or a dedicated mold for your injection molding process.

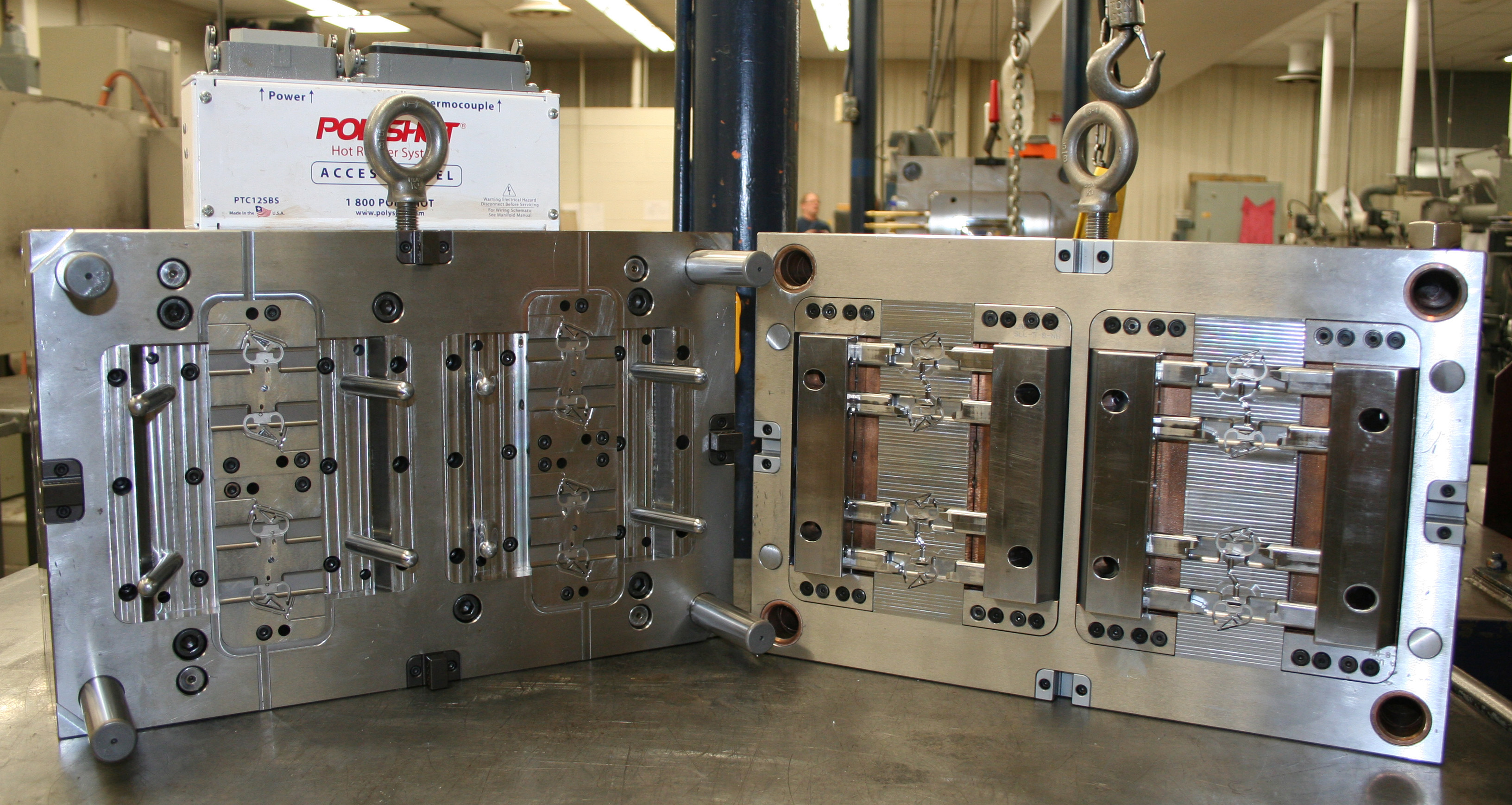

injection mold components

To understand the difference between a dedicated mold and a toolset you need to know the specialized parts of an injection mold that are vital in efficiently shaping molten plastic into the desired product. These mold components include:

- Mold Base (Mold Plate/Frame): As the foundation of the entire mold, this part provides strength and rigidity to withstand high injection pressure. It is also the central hub for integrating other mechanical components.

- Cavity and Core: These components are the mold's heart. The mold cavity forms the part's external features, allowing for different surface finishes and textures. Meanwhile, the core creates internal features like holes and recesses.

- Inserts: These are specialized components placed within the cavity to create features like threads.

- Nozzle and Sprue Bushing: This duo is the gateway for injecting molten plastic resin into the mold. The nozzle regulates flow and ensures proper injection speed, pressure, and smooth flow. The sprue bushing holds the nozzle in place for precise alignment.

- Runner System and Gate: This network of channels efficiently distributes the molten material throughout the mold. Gates at the runner's end help control plastic material flow into the mold cavity and maintain pressure.

- Ejector Pins: These pins on the moving mold plate push the injection-molded plastic part out of the cavity after solidification.

- Cooling and Venting System: The cooling system controls mold temperature with circulating water or oil channels for heat transfer. Meanwhile, the venting system expels air and gases from the cavity to prevent air pockets and maintain part quality.

- Mold Interlocks: These locking mechanisms ensure proper alignment between mold components. They minimize molding errors like flashing and warping in the injection molding machine.

In dedicated injection molds, the mold design is tailored to achieve quality and efficiency targets. With this approach, all mold components are fabricated to manufacture a specific part.

Meanwhile, injection molding toolsets offer a flexible and efficient approach to tool design. While the mold cavity remains unique to each product, the rest of the tool consists of standardized parts. Master mold frames play a crucial role in crafting this system. The pre-engineered frames feature standardized inserts for runners, gates, leader pins, support pillars, sprue bushings, side actions, and ejector systems. This approach is made possible through the use of master mold frames. The toolset is the only piece of the mold required to be designed and machined to produce a particular part.

DESIGN AND FUNCTIONALITY OF INJECTION MOLDs

A well-designed and functional mold is the cornerstone of an efficient plastic injection molding project. Your project might be a fit for a dedicated mold or the cost-efficient method of a toolset in a master mold frame, depending on the product design and requirements.

Dedicated molds are custom-built, allowing for intricate designs, complex functionalities, and highly optimized heating and cooling channels for precise part quality. However, this specialization requires more time to design and manufacture.

Toolsets prioritize efficiency using a modular design. They utilize a pre-fabricated mold frame with standardized components, eliminating the need to remake different mechanical elements for each new project. Although the part and project scope need to fit to use this system of tooling.

DEDICATED MOLD VS TOOLSET

There are several factors to consider when selecting the right tooling for your injection molding project.

Customization

Dedicated injection molds are crucial to building tailored plastic products. Through customization, molders can incorporate intricate details, tight tolerances, and features like undercuts or side actions. Toolsets also offer the same degree of customization as long as the design fits the requirements for a toolset. By modifying the master mold frame or replacing its interchangeable inserts, molders can customize the mold to meet product specifications.

Design Complexity

Custom plastic injection molds are ideal for projects with intricate design complexities. Manufacturers can incorporate intricate features, multiple cavities for high-volume production, and specialized functionalities. Toolsets are also versatile since some of Crescent Industries' master mold frames come with built-in advanced features. The frames have side actions with adjustable travel and are compatible with both cold and hot runner systems, providing greater versatility in molding operations.

cost

Custom molds may have high upfront costs since clients shoulder the expense of building the entire mold unit to produce a customized part. Utilizing a master mold frame can be less costly, as it's not necessary to create an entire mold base. These toolsets are still produced using hardened tool steels and made to the standards of production quality tools. The only difference is the inserts require design and machining. This results in significant savings on labor, and design expenses.

Injection-Molded Parts or Injection Molding Tools: We Got You Covered

Dedicated injection molds excel in precise part shaping and can meet the intricate designs of your product. However, toolsets from master action frames offer lower initial costs, reduced lead times, and versatility, depending on your project and molding cycle.

As one of the best injection molding companies, Crescent Industries can help you decide which method is best for your project. We guarantee superior injection-molded plastics and dependable tooling solutions. We also boast a range of mold frames and injection molding equipment that can accommodate different toolsets for seamless production processes.

Whether you’re seeking top-quality custom injection molding services or comprehensive pre-made toolsets, Crescent Industries is your trusted partner. Contact us today to discover how we can elevate your manufacturing endeavors.

Topics:

Related Articles

-

May 12, 2025

The Role of Hot Runners in Injection Molding

Read MoreBefore the invention of hot runner systems, manufacturers used cold runner injection methods. These...

-

Apr 23, 2025

How Long Does an Injection Mold Last? | Durability Factors

Read MorePlastic injection molds can manufacture custom parts in numerous industries with great accuracy and...

-

Apr 10, 2025

How Are Injection Molds Made for Plastic Manufacturing?

Read MoreDo you have a part design and need an injection mold built? Are you interested in finding a tooling...