75 YEARS OF INSIGHT, KNOWLEDGE, & EXPERIENCE AT YOUR FINGERTIPS

Injection molding & mold building resources

Our Resources Page is designed to provide assistance and relevant information on a wide range of topics, helping your organization achieve success and supporting you throughout every stage. Explore our resources below, including insightful videos, detailed guides, and checklists.

-

Design for Manufacturing

- Learn about the importance of why our engineers utilize the concept of Design for Manufacturability from the very start of a project.

Watch the DFM video here! - This guide covers the basic principles of the Design for Manufacturability strategy.

See Guide here! - Use this checklist to pave the way for a successful molding project utilizing Design for Manufacturing principles.

Find Checklist here!

- Learn about the importance of why our engineers utilize the concept of Design for Manufacturability from the very start of a project.

-

Selecting the Proper Plastic Resin for Your Project

- These resources take a close look at how to select the best materials for your plastic injection molding project.

Watch Video on Choosing a Resin! - This resin raw material guide breaks down the different plastic materials and when it is best to use them.

Review the Material Guide!

- These resources take a close look at how to select the best materials for your plastic injection molding project.

-

Part Design Guidelines

Learn about best practices for injection mold product and device design.Get the Part Design Guide Now! -

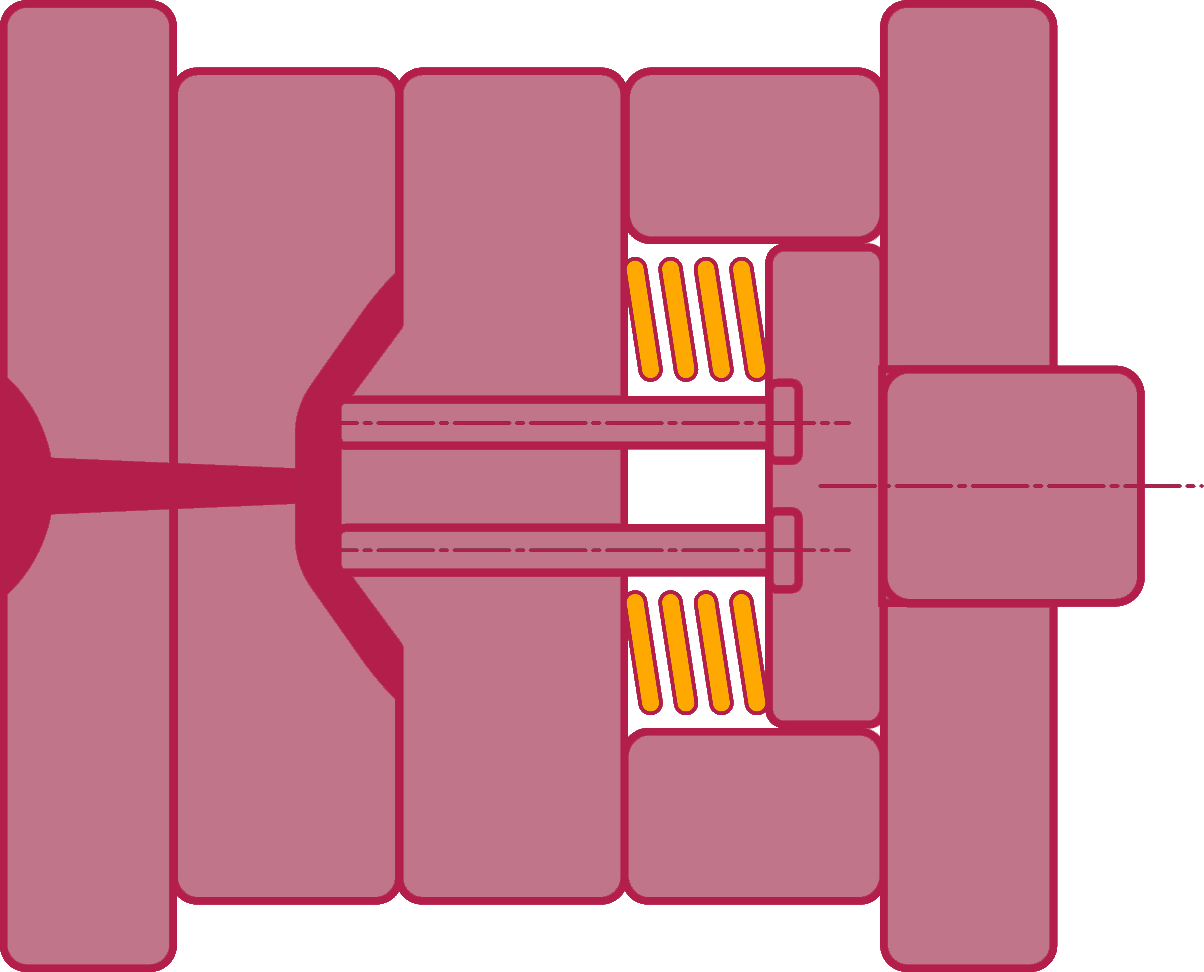

Injection Mold Building Resources

- Learn more about the many different kinds of injection molds that are available.

Watch Mold Types Video! - How to Get the Most from your Injection Mold Tooling: An Essential Guide for Decision Makers. Check out the Tooling Guide Now!

- Sign up to receive this helpful guide about mold design principles.

Register to Receive the Mold Design Guide! - Having your injection molder build the tooling you need has some great benefits.

Watch Video Here! - This video explains Crescent Industries’ proprietary Master Action Molding System, and how it saves time and money as compared to using a conventional stand-alone mold.

Watch the Benefits of Master Action Molds! - Learn 10 important factors that impact injection molding costs.

Discover the 10 Factors Now!

- Learn more about the many different kinds of injection molds that are available.

-

Injection Molding Process and Post-Molding Operations

- Is it better to injection mold or 3D print your device or product?

Watch Video to Learn the Difference! - This guide covers everything you need to know about plastic injection molding.

Read the Complete Guide Now! - This white paper takes a deep dive into the scientific injection molding principles.

Investigate the Principles! - As part of the assembly process and post processing services, learn about the proven bonding methods we utilize.

View Video on Assembly Processes! - Learn more about plastic part decoration services.

Watch Different Decorating Methods! - In this video, we take a look at the most common types of injection molding defects, and how they can be prevented.

Check Out the Video Now!

- Is it better to injection mold or 3D print your device or product?

-

Important Things to Consider When Selecting an Injection Molding Partner

- This video provides some helpful tips on how to choose the best injection molder to fit your needs.

60 Second Quick Tips Video! - This buyer’s guide further discusses the best way to select your next injection molding partner.

Make Informed Decisions with this Guide! - Our handy tonnage calculator helps to determine the size press needed to produce your part or device.

Use the Calculator Tool Now! - Interested in medical device contract manufacturing? This information covers all you need to know.

Unlock Medical Device Contract Manufacturing! - Learn how injection molding experts achieve product success.

Watch a Customer Testimonial!

- This video provides some helpful tips on how to choose the best injection molder to fit your needs.

Discover what sets crescent industries apart

Now that you've explored our resources, take a look at our case studies.

These case studies showcase how we address complex challenges with customized solutions tailored to each client’s specific needs. Explore the examples below to see how our expertise in injection molding and mold building, paired with our dedication to excellence, has delivered results for our customers.

FROM CONCEPT TO REALITY: CRESCENT'S ROLE IN MASS PRODUCING A MEDICAL DEVICE

Bringing a medical device from idea to mass production is a complex and demanding process, but with the right partner, it becomes a seamless journey. In this case study, we explore how Crescent Industries collaborated with a customer to take their groundbreaking patient monitoring device from a 3D-printed prototype to a high-quality, market-ready product.

By leveraging our expertise in Design for Manufacturability (DFM), precision tooling, and efficient injection molding processes, we helped streamline production while maintaining the highest standards of quality and reliability.

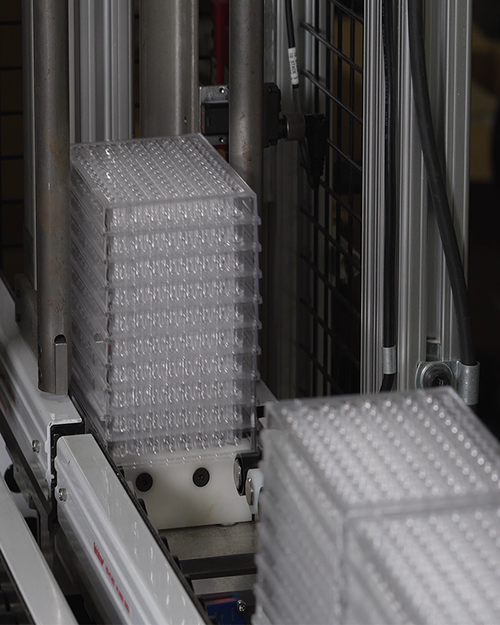

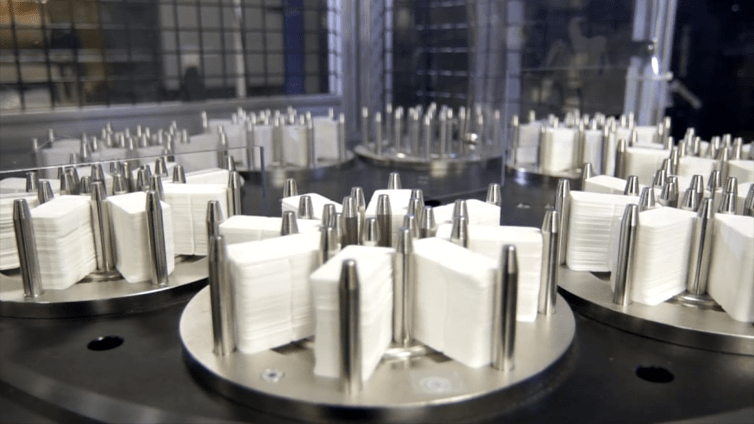

Winning Diagnostic Plate Business by Delivering a Custom Automated Injection Molding Solution

When a leading diagnostic OEM needed to produce 19 unique versions of a critical diagnostic plate, they required more than just a molding supplier—they needed a strategic manufacturing partner. Crescent Industries delivered a complete, turnkey solution: from precision mold building to custom automation and high-volume injection molding. Our in-house engineering team developed an automated system tailored to manage part variation, improve cycle times, and ensure consistent quality across all versions.

This case study shows how our full-service capabilities and automation expertise helped win the project—and how we can help you take on complex challenges with confidence.

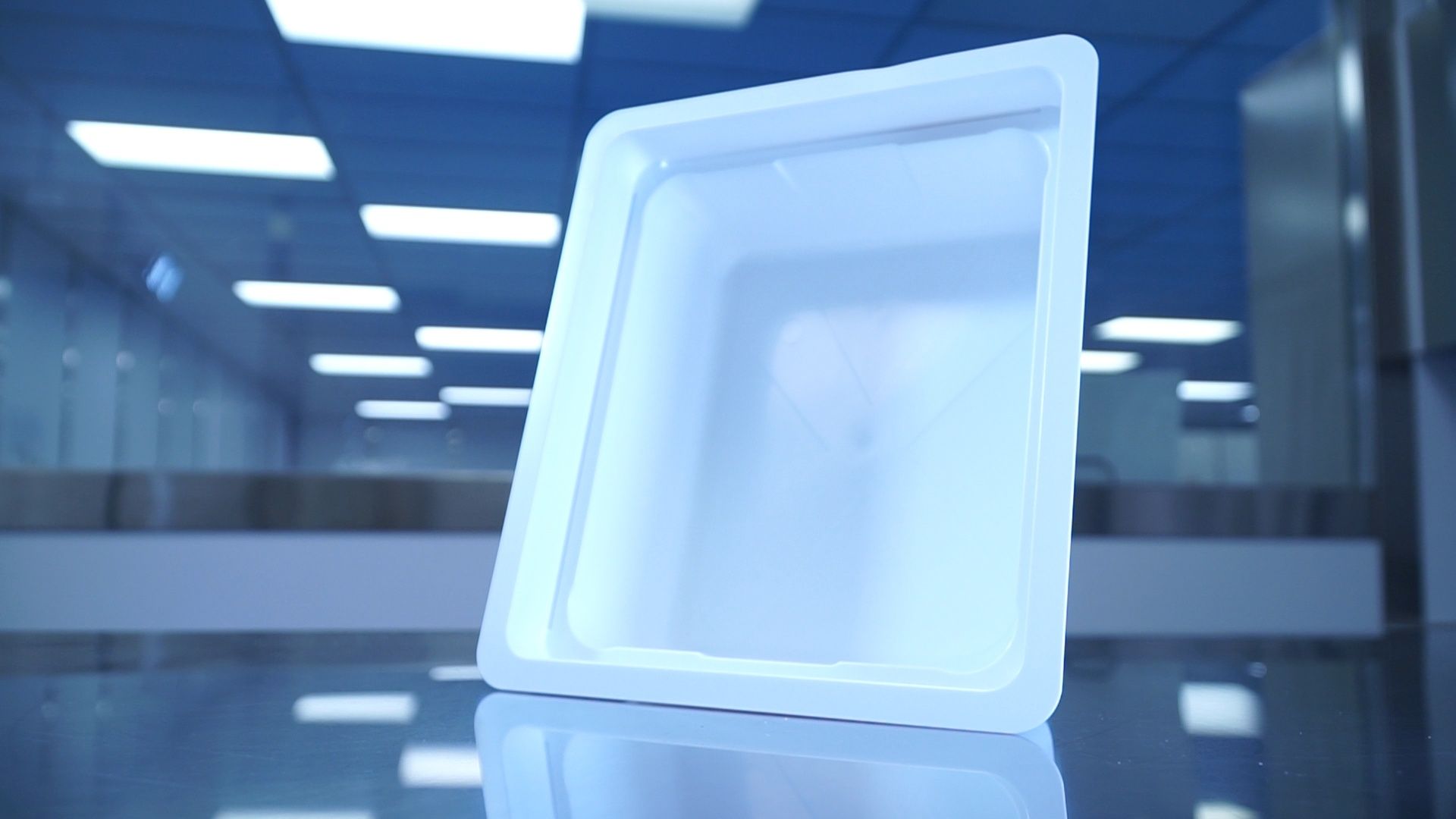

Crescent Industries Delivers a Win by Offering a Full-Service Cleanroom Molding Solution

When a pharmaceutical packaging company needed a reliable partner to produce a sterile, high-volume RTU tub, they chose Crescent Industries for more than just cleanroom molding. We designed and built a custom Class 101 mold, implemented automation to reduce contamination risks, and collaborated with our resin supplier to create an anti-static material—all while scaling production in our ISO 8 cleanroom.

This case study shows how our full-service capabilities streamlined their supply chain and ensured quality from start to finish.

Learn How DFM Solved Quality Issues for a Client's Medical Device

A leading medical device manufacturer struggled to produce quality parts for their ultrasonic bone-healing device. Despite their efforts, they couldn't consistently achieve the necessary part quality for performance and safety. Crescent Industries stepped in with our Design for Manufacturability (DFM) approach. By identifying key areas for improvement in the part design and tooling, we worked closely with the client to revise the design and build custom tooling that would deliver the quality they needed. The result? Enhanced part consistency, reduced production costs, and a quicker time to market.

Find out how our DFM expertise transformed their production process and led to a successful outcome.

CRESCENT DOUBLES PRODUCTION CAPACITY WHILE CUTTING PRODUCTION COSTS BY 18%

In this case study, we showcase how Crescent Industries helped a client achieve remarkable production gains and cost savings through strategic investments in new tooling and automation. By implementing advanced mold designs, state-of-the-art machinery, and automated processes, we were able to streamline production, reduce labor costs, and significantly increase output.

Dive into the full story to explore how our innovative approach to injection molding led to a win-win solution for both efficiency and savings.

Crescent Industries Streamlined Mold Design & Mold Builds for a Complex Orthopedic Device

Discover how Crescent Industries partnered with a leading orthopedic surgical device manufacturer to transform complex production challenges into streamlined, cost-effective solutions.

By implementing advanced mold simulation and precision engineering, we developed 13 high-precision components across five distinct injection molds. This collaboration not only enhanced product quality but also optimized the manufacturing process, ensuring seamless integration and reliability in every surgical instrument.

Blogs

-

Jun 30, 2025

How Medical Overmolding Enhances Devices: Key Benefits and Applications

Read MoreThe number of medical devices hitting the market is constantly rising to meet the healthcare...

-

Jun 18, 2025

A Proven process for transferring your injection mold tooling with confidence

Read MoreTransferring or moving an injection mold is necessary sometimes especially in regulated and...

-

Jun 10, 2025

What to Ask Before Choosing an Injection Molding Company

Read MoreInjection molding offers a range of benefits to companies across various industries, including...